Reverse Osmosis Systems

REVERSE OSMOSIS Water Treatment

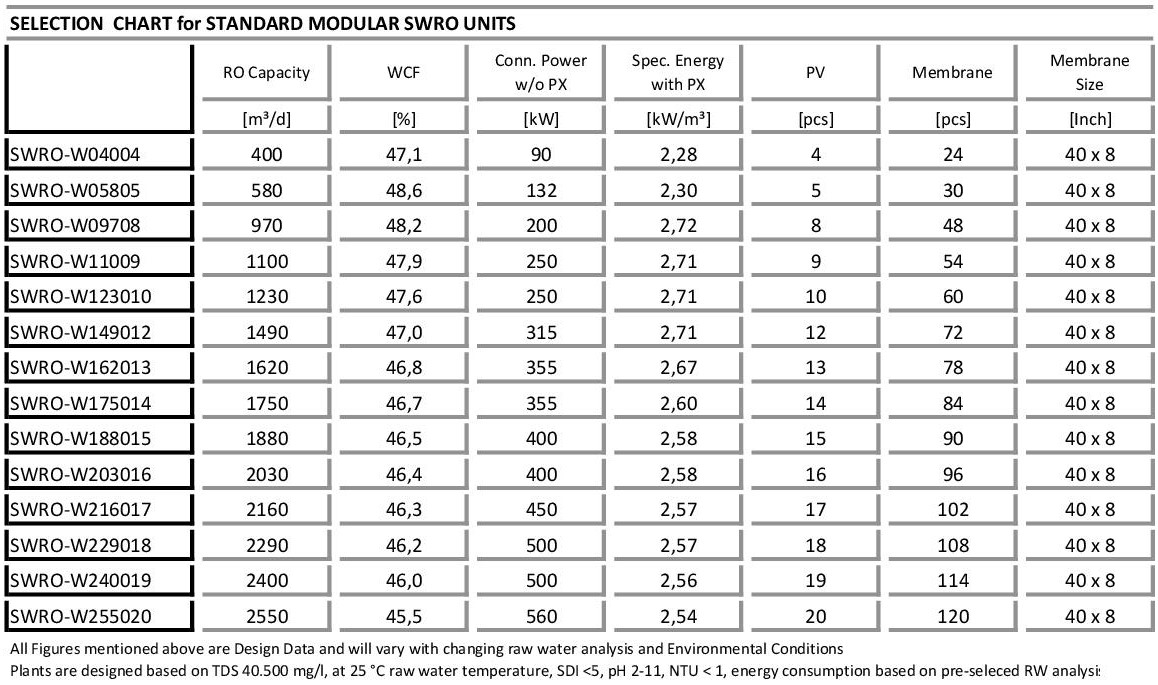

WAV offers you the suitable, standardized but also individual solutions for a multiplicity of applications by the disposition of stand-alone solutions or combined technologies as well.

Not the development of components alone place an award on the market, but also the ability to combine these components together to form compartments, or a full, well operating system. That is what we can do for our customers

The Membrane Technologies treatment processes come along with us since many decades. Partially the technologies have been developed, or that have been extended by new process designs.

By technological improvement, the efficiency of processes could have been increased clearly, especially in the field of energy saving and recovery technologies.

The wide spread of high efficient membrane processes, have extended number of supporters due to their reliable function for miscellaneous applications, and therefore are counted in interaction with classical water treatment methods, pre-treatment and post treatment and polishing processes, for almost all waters like surface waters, well waters, brackish and mostly sea waters.

PROCESS DESIGN

The raw water normally available from seawater sources is, however, never directly suitable for drinking purposes.

Due to Osmosis process, which is reversed by applied pressure, the water flows from the saline solution (Raw Water), through a semi-permeable membrane to the diluted solution (Permeate). Salts are kept with very high retention rate (> 99.5 %) and increase the salinity in the saline solution (Concentrate).

The objective of Reverse Osmosis desalination process is to produce safe drinking water. Generally, WAV SWRO modular desalination units consist of:

* Necessary Pre-Treatment and Pre-Conditioning

* Micro-Filter, 5µm absolute

* High Pressure Pump, preferable Multi-Stage Type

* Booster Pump (in case using Pressure Exchanger PX)

* Energy Recovery Units (PX Modules, i-Save, TC, Pelton Turbines, etc.)

* Prefabricated, Extendable, Modular RO Assembly

* Necessary Instruments

* CIP System

* pH-Adjustment or Re-Mineralization

* Disinfection by Chlorine, UV, etc.

* Electric Panel, SCADA, PLC, HMI

With WAV MODULAR SWRO units the salinity from available pre-treated raw water source is reduced by the selected high performance membranes with an efficiency of clearly > 99.5 %, providing a treated water quality based on WHO drinking water standards. The RO permeate is perfectly suitable for further polishing treatment steps in order to receive pure or ultra-pure water for industrial purposes.

The applied Reverse Osmosis desalination process mentioned above, mostly has to be extended by specific required pre- and post-treatment process-steps in order to convert the original raw water on the one hand into a water quality accepted by the membranes and on the other hand to convert the permeate into the desired treated water quality, as there are :

> Screening Systems, coarse or/and fine screens

> Pre-Disinfection by Ozonation, UV Light, Hypochlorite

> Primary Sedimentation

> Lime Softening

> Strong Acid Cation Exchange Softening

> Classical Coagulation/Flocculation

> Enhanced Coagulation

> Electro-Coagulation

> Oxidation, by Permanganate

> Air Stripping and Aeration

> Dissolved Air Flotation (DAF)

> Ultra-Filtration (UF)

> Hydro Pneumatic Flocculation

> Sedimentation / Clarification

> Filtration, self-cleaning filter, granular media filters

> Filter back washing systema

> Oxidation Filtration incl. regeneration system

> Activated Carbon Filters (ACF)

> Backwash Water Recovery

> Post-Disinfection, by Ozone, UV

Based on the pre- and post-treatment processes mostly necessary to ensure a proper operation of the Reverse Osmosis System, WAV engineers will design among the mentioned above pre-treatment steps, the most suitable pre- and post-treatment steps.

This means that especially surface waters are affected by seasonal influences and have a high microbiological and colloidal fouling potential. So the Original Raw Water has to be treated more elaborate, to be fed to the Modular RO system and finally being used for the desired application.

Inadequate pre-treatment often results in more frequent cleaning of the membranes to restore the permeate capacity and salt rejection. Therefore, the lost performance and the costs for cleaning can be significant.

As one pre-treatment process for RO and/or NF, UF becomes more and more popular. Another pre-treatment technology, upstream to RO and/or NF Membrane Processes, is a standard physical/chemical treatment, which enjoys still great popularity among engineers.

For domestic use and health care, we put our especial attention on the treated water quality and the compliance with the valid drinking water standards.

-p1.jpg)

Typical P&ID for Modular Plant Size SWRO-W255020

Plant ADVANTAGES of WAV MODULAR, EXTENDABLE UNITS

+ Compact Design due to standardised Components and Compartments

+ Low Foot Print by direct connecting of Compartments

+ Modular System, therefore Extension and Frame-Adjustment possible

+ High Performance Membranes, therefore highest possible Permeate Output

+ Lowest possible Energy Consumption due to Most Advanced modular Pressure Exchanger (PX) Energy Recovery Systems

+ Extended Life Time due to Automatic Flushing after Shut down and integrated chemical Cleaning System

+ Complete Process- and Plant Design is performed by the engineers of WAV

+ Reliable, Simple and Safe Operation

+ Clear Visualized, Scalable and Controllable Process by SCADA System

+ Mobile Solutions

+ Automatic Operation, thanks to Modern Technologies

+ Easy Access for Service Works

+ Reliable, Premium Quality Components from First Class international Well-known Producers

+ Secured Availability of Spare Parts

Plant D Design REQUIREMENTS

WAV MODULAR SWRO units are designed principally based on the valid available environmental European standards, but for each individual case, we review the details, considering our customer standards required for distributing or usage of the treated water.

The minimum required data for our design are:

* Average daily water consumption during dry- and wet season for the population to be supplied

* Required treatment plant capacity in [m³/d]

* Complete Water Analysis

* Climatic Conditions, Humidity, max./min./ave. Temperature [°C]

* Mean Sea Level MSL

* Any required water quality standards for the treated water (when different to WHO)

* Where to dispose concentrate or any other process wastewaters, etc.

We serve you with the necessary questionnaire to be filled in.

Plant EXECUTION

WAV Modular, Extendable Sea Water Reverse Osmosis Systems consist of first class pre-fabricated stainless

steel-, powder coated or occasionally hd-galvanized steel skids, where the pressure modules, piping, valves, instruments and accessories are pre-assembled. Inter-connecting high-pressure pipes & fittings are made of high corrosion resistant Duplex or S-Duplex stainless steel. Low-pressure piping is made of PVC/PP/PE.

Equipment like micro-filter, pressure modules, energy recovery devices, different types of pumps, valves, measuring & control instruments, are pre-assembled, preferably on skids and tested.

Above mentioned compartments and Electric cabinets, SCADA, PLC, HMI, power and control cables and other auxiliary parts and equipment, are shipped as a complete functioning plant, or can be provided as individual compartments. High efficient membranes (factory tested) are inserted right before the commissioning to keep them as long as possible in conservation solution, in order to secure the performance of the membranes.

At site, the mentioned compartments will be put on reinforced concrete foundations and be connected together.

It needs a few hand movements to complete the plants, and make it ready for commissioning and start up. The treated water quality, shall be based on any national or international water quality standards (e.g. WHO) for drinking water and/or as desired by customer.

The INNOVATIVE DESIGN of RO DESALINATION SYSTEMS

Trust the design of WAV Process Engineering GmbH. Innovative Thinking is our Tradition in Design Solutions, which supports the development of our customers.

We design Standardised, Modular, but also customised Reverse Osmosis Desalination Systems and compartments, as well as industry-specific solutions of water- and wastewater treatment.

The processes are based on the latest findings, but with respectable, acceptable and proved test runs and performance results.

Innovative technologies and processes, find considerations in our design, but also well established and carefully tested membrane treatment processes, as they can be used occasionally in remote regions.

The plants can be designed as space-saving compact units and on demand as standard designed RO plants.

A modular system is to be installed there, where a fast mounting is required on the one hand, and a variation of quantity is expected on the other hand. The extension can be performed less time consuming and consequently with lower costs.

The design is performed on basis of 2D- and/or 3D.

Continuous Tele-Monitoring of the designed plants, shall assist the customer with the fast Error Detection and Troubleshooting at low expenses.

A well-designed process and a good continuous operation performance of a plant shall be achieved and secured, by the installation of a SCADA-/ HMI-/ PLC-System, which is programmed carefully under supervision of our specialists.

Contact

www.wav.co.at

WAV Process Engineering GmbHFraunhoferweg 6a

4030 Linz / AUSTRIA

+43 (0)732 23 23 65

Search site